Why PCBasic’s Advanced SMT Lines Revolutionize Modern Electronics

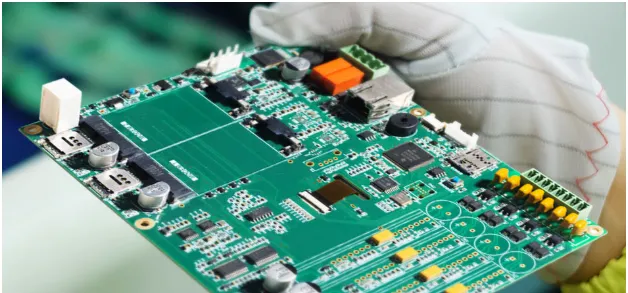

In today’s fast-paced electronics industry, precision, speed, and flexibility are everything. That’s where PCBasic stands out — with nine advanced SMT assembly lines, we deliver high-quality PCB assemblies that power the world’s most innovative products.

Moreover, PCBasic’s SMT lines are equipped with AI-powered inspection systems, reducing human error and increasing yield. Their automated processes handle even the tiniest components with unmatched accuracy, making them ideal for complex circuit designs used in smartphones, medical devices, and industrial equipment. This level of technology not only boosts efficiency but also supports rapid prototyping and custom builds, giving PCBasic a competitive edge in the electronics manufacturing industry.

Also Read: How to Choose a Franchise – Match Your Interests, Match Your Passion

What Are SMT Lines?

SMT stands for Surface Mount Technology. It’s the method used to place electronic components directly onto the surface of printed circuit boards (PCBs). These components are small, but they are the heart of every modern electronic device.

Traditional methods used through-hole mounting, which was slower and bulkier. In contrast, SMT lines allow for smaller, lighter, and more complex devices. With PCBasic’s use of advanced SMT lines, manufacturers can now produce high-quality electronics at scale and speed.

Engineered for Performance and Scale

Whether you’re building a smart wearable, a communication module, or an industrial control system, PCBasic has the infrastructure to support your needs. Our SMT lines are optimized for both prototype runs and mid-volume production, enabling fast turnarounds without sacrificing quality.

What You Can Expect from Our SMT Lines

- High-Speed Pick-and-Place

Our machines are built for speed and accuracy, placing thousands of components per hour with tight tolerances. From microchips to fine-pitch BGAs, nothing is out of reach.

- 3D SPI and AOI at Every Step

We don’t compromise on inspection. Solder paste is verified with 3D SPI, while AOI systems catch placement or soldering defects in real-time—before boards move forward.

- X-ray for Complex Assemblies

Need BGA, LGA, or QFN packages? No problem. Our inline X-ray ensures every hidden solder joint is inspected thoroughly.

- Clean and Controlled Processes

From ESD-safe environments to nitrogen reflow options, every detail is managed to protect component integrity and ensure product consistency.

Built for Flexibility

No two projects are alike. That’s why our SMT lines are designed for quick changeovers, allowing us to shift between different board types and BOMs with minimal downtime. It’s the perfect solution for clients who require agility and responsiveness.

More Than Just Machines

Behind our advanced lines is a skilled team of SMT engineers and quality specialists who understand what it takes to build reliable electronics. We follow IPC standards, offer traceability throughout the process, and keep our clients informed at every stage.

Your Trusted PCBA Partner

PCBasic is more than a factory. We are a manufacturing partner who cares about your product’s success. From DFM support to post-assembly testing, we’re committed to helping you launch faster, smarter, and with full confidence in your electronics.

Need high-quality SMT assembly for your next project?

Get in touch with PCBasic and discover how our advanced lines can give you a competitive edge.